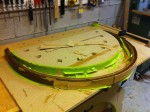

Bent Lamination

A project I’m working on incorporates a 40″ diameter arch as a key design feature. This being the first bent lamination I’ve tried, I took some pictures I figured I’d share here. I chose to use epoxy for the lamination because I couldn’t seem to find urea formaldehyde glue anywhere around here, and I figured that creeping of yellow PVA glue would cause problems. And I was too impatient to order anything online.

I used a two-part form, male and female, cut from cheap particle board and wrapped with masking tape. The clamping process was a bit involved. To get the female form over the part, the best idea I had was to lightly clamp everything in place minus the female form and then use a long pipe clamp to hold the ends of the arch close enough to in place to get the female form over it all. Then I had to remove all the F clamps, leaving the pipe clamp to keep it sprung in place, install the female form, and then put all the F clamps back. As you can likely imagine, that was a pain in the rear, so I’m going to try something different next time, I think.

So … when your glue comes with an instruction manual, it’s a good idea to read it. I actually did. Honest. But… it’s an even better idea to pay attention, especially when it contains words like “exothermic”. I mixed up about 1/3 more epoxy than I ended up needing and I left the remainder in a plastic cup on the floor while I clamped up the assembly. Now, that took all of about 20 minutes. But the thing about epoxy is that when it cures, it gets warm, and when it’s warm, it cures faster. See the circle there? I was interrupted in my clamping by the smell of melting plastic. Fortunately, I smelled it before it got bad and I was able to peel it off the increasingly hot block of epoxy before anything really bad happened. Looking more carefully through the manual, I guess a key factor in the heat build up here was that my mixing cup was somewhat deep, which created a thick volume of curing epoxy where heat could build up. It’s worth noting that it was about 1″ deep in the cup, and the cup was about 1 1/2″ or 2″ in diameter. It’s also worth noting that the leftovers in the cup were quite solid, yet the squeeze out on the actual work piece was still completely liquid. So keeping it in a shallower mixing pot would likely have prevented the problem.

The manual pretty clearly states that a thick enough volume of curing epoxy will get hot enough to ignite combustible materials, so if you try it out, keep that in mind and be safe.

Comments: 1

[…] sister and brother in law. It features a live edge top that I flattened with a router sled and a laminated arch on the base. This is walnut with a clear danish oil finish and a bit of wax. The top is hand […]

Comments are closed.